The links below are affiliate links. This means every time you purchase through these links, I earn a small commission.

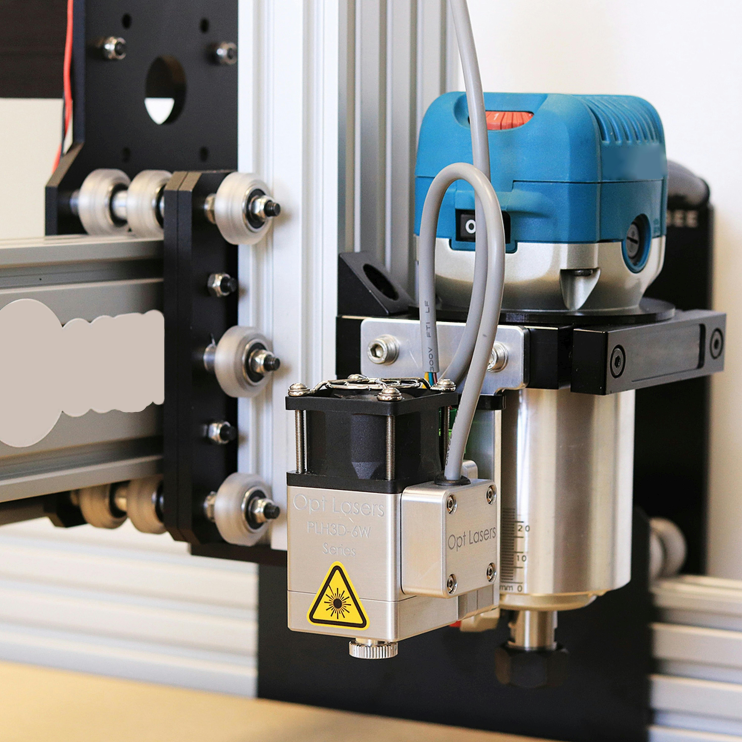

The world of CNC machines is vast and ever-evolving, and one of the most exciting advancements in recent years has been the integration of diode laser attachments. These powerful tools have revolutionized how hobbyists and professionals approach projects, offering precision and versatility. As someone who has navigated the complexities of choosing the right diode laser attachment for my CNC(Longmill 30×30), I’ve discovered that understanding the differences between 5W, 10W, and 20W lasers is crucial. Today, I’m here to share my insights and experiences to help you make an informed decision for your projects. Whether you’re engraving delicate designs or cutting through materials, there’s a diode laser attachment CNC that’s perfect for the job.

The Basics of Diode Laser Attachments

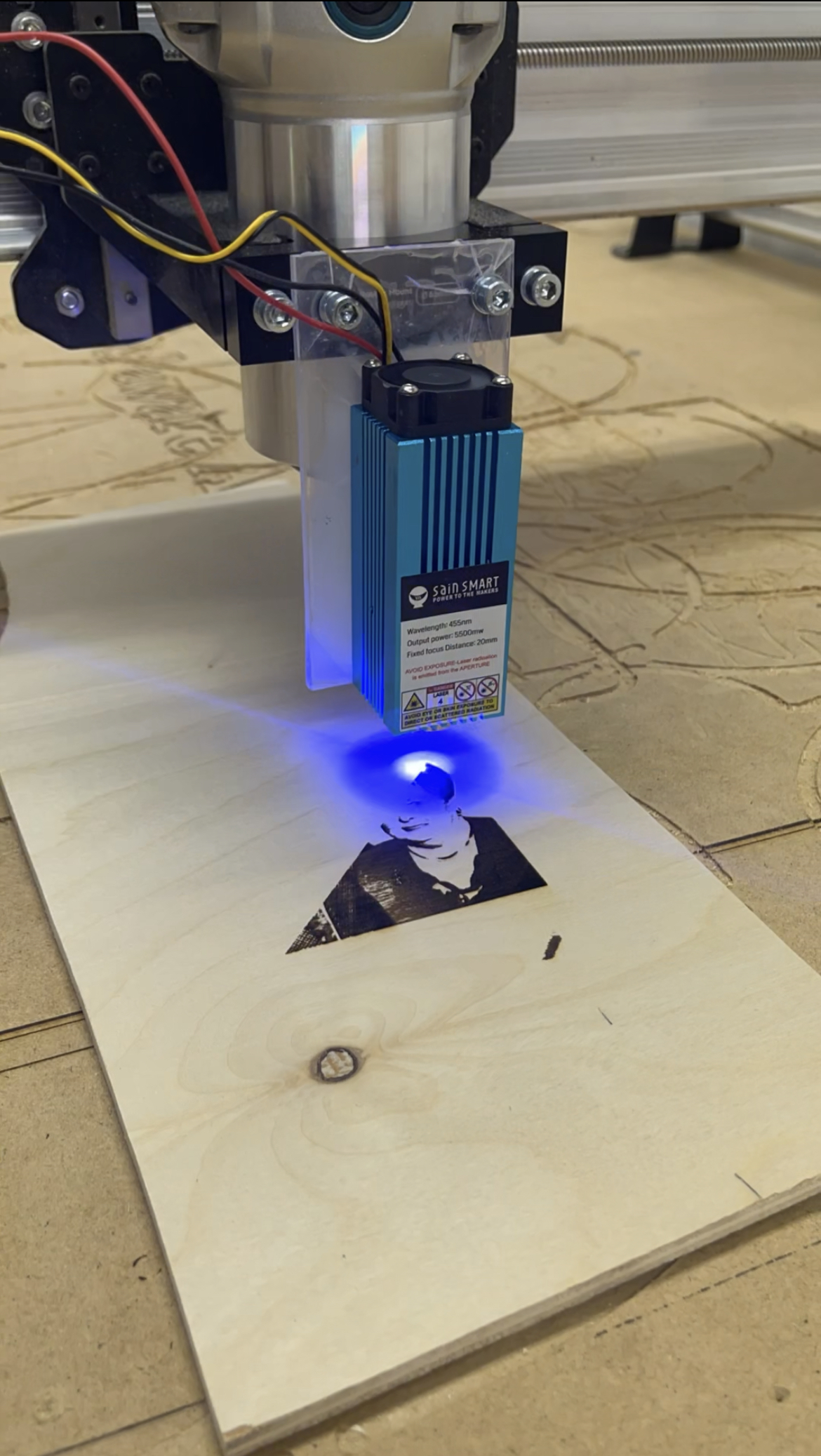

Diving into the world of diode laser attachments was a game-changer for my projects, and I’m eager to help you get the lay of the land. These nifty devices aren’t just add-ons; they’re your ticket to elevating your CNC machine’s capabilities, allowing you to shift seamlessly between engraving and cutting with precision. At their core, diode lasers concentrate a beam of light to etch or slice through materials. The wattage, essentially the laser’s horsepower, directly influences what you can achieve. But here’s the thing, it’s not all about brute strength. The effectiveness of a laser also hinges on factors like the precision of the beam, the wavelength, and the quality of the lens. Understanding these basics isn’t just helpful; it’s essential for choosing the right tool that aligns with your vision, ensuring your projects not only come to life but shine. Let me guide you through these fundamentals, sharing the insights I’ve gained to empower your decisions in the thrilling arena of diode laser attachments.

A 5W Diode Laser Might be all You Need

Getting into laser engraving and cutting was a journey of discovery for me, and starting with a 5W diode laser was a decision I’ve never regretted. Here’s the scoop: if your passion lies in engraving, the 5W laser is your go-to. I’ve used it to create detailed and precise designs on various materials, from wood to leather, and the results have always been impressive. It’s amazing how something so seemingly modest in power can produce such beautiful, intricate work. It’s an ideal choice for hobbyists like me or for anyone focusing on engraving over cutting. The affordability and efficiency of a 5W laser make it a standout choice, allowing you to achieve incredible results without needing to invest in higher wattage options. So, if engraving is your primary goal, a 5W diode laser might be all you need to bring your creative visions to life. While this is not to say that a 5W laser CAN’T cut through thin materials, be aware that the process will be slow and will require multiple rounds to make it through the material, potentially making the edges darker than you’d like.

If you’re looking for an inexpensive but reliable starting laser, this is the one that I use.

***ALWAYS double check that you’re CNC and Diode Laser attachment are compatible***

Stepping up to 10W & 20W for Cutting Power

Embarking on more ambitious projects meant embracing the need for more muscle, which led me to the world of 10W and 20W diode lasers. Trust me, the leap in wattage is not just about bigger numbers; it’s about unlocking new possibilities. With a 10W laser, I found myself breezing through projects involving thin plywood, marvelling at the clean cuts and swift execution. The precision remained top-notch, but the added power significantly reduced the time I spent on each piece.

However, stepping up to a 20W laser is a no-brainer for someone who wants the speed and power to execute more products in less time. The difference is night and day when dealing with thicker or tougher materials. You could achieve deeper cuts without sacrificing the quality of the finish, which is a game-changer for some. Of course, navigating this new terrain of higher wattage requires you to double down on safety measures, but the results, I believe, will speak for themselves. Whether it is for personal projects or pieces intended for sale, the capability to efficiently cut through a variety of materials opens up a whole new world of creativity.

You can browse 5 W, 10W & 20W diode lasers here.<—

Considerations for Choosing the Right Wattage

When I first ventured into selecting the right wattage for my diode laser attachment CNC, I felt like I was navigating a maze. Let me guide you through some key considerations that helped me make my choice, hoping it clears the path for you too. It’s not just about how much power you can wield; it’s about precision and speed alignment with your project goals. Think about the types of materials you’re eager to work with. Are they mostly thin and delicate, or are you aiming to slice through thicker boards? The thickness and material type should heavily influence your decision.

Also, ponder the intricacy of the designs you plan to create. A higher wattage laser can handle more demanding cutting tasks but remember, for detailed engravings, a lower wattage might serve you just as well, if not better, due to its finesse.

Your budget is another cornerstone of this decision-making process. Higher wattage means a higher price tag, so weigh the benefits against your financial comfort zone. Lastly, don’t overlook the importance of safety and space. More powerful lasers demand stricter safety protocols and possibly more space to operate safely.

Navigating these considerations helped me pinpoint the perfect wattage for my projects, and I’m confident it will illuminate your path too.

My Personal Recommendations

So which laser attachments should you start with? After spending considerable time experimenting and exploring the capabilities of various diode laser attachments, I’ve honed in on some personal recommendations that I believe can serve as a guiding light for your journey. If you’re just dipping your toes into the world of laser engraving, a 5W laser is an incredible starting point. Its affordability and precision make it an ideal choice for those who are curious about engraving and looking to achieve detailed designs on softer materials without a hefty upfront investment. Moving up the power scale, a 10W laser stands out as a versatile contender, striking a balance between the ability to engrave and the newfound capability to cut through materials like plywood with ease. It’s a step up that I found particularly rewarding for expanding project possibilities. Lastly, for the professionals or avid hobbyists out there, investing in a 20W laser could revolutionize your work, offering the power and depth needed to tackle a broad range of materials and projects. Each wattage has its niche, and aligning that with your aspirations will pave the way to truly remarkable creations.